Waterproof connectors are essential in Industrial Machinery applications, offering robust protection against water, dust, and harsh conditions. They ensure enduring performance and reliable data/power transmission in challenging industrial environments. Safety is enhanced, and maintenance becomes easier with quick-connect mechanisms. Waterproof connectors extend machinery lifespan, comply with industry standards, and play a crucial role in ensuring efficient and safe industrial operations.

Below are some examples of applications with waterproof connectors:

- 1. Laser Waterpipe Welding Devices:

Laser water pipe welding is a precise and efficient technique for joining sections of pipe used in water transport, creating strong, leak-proof welds with minimal heat distortion. This method finds applications in diverse areas, from standard plumbing and industrial water systems to specialized projects like desalination plants, prioritizing long-term pipe integrity and leak prevention. Key advantages include highly precise welds, increased welding speed, and minimal material deformation. These benefits are achieved through sophisticated control and monitoring systems that rely on robust connectivity. Sensor connectors, often compact and rugged M8 or M12 circular connectors, interface with crucial sensors like seam trackers, ensuring the laser accurately follows the weld joint, and temperature sensors, monitoring heat input for optimal weld quality. Communication connectors, including industrial Ethernet, serial connections (RS-232/485), and fieldbus connections (e.g., Profibus, CANopen), facilitate seamless communication between the laser source, beam delivery system, sensors, and the main control unit. Input/output (I/O) connectors further enhance safety and control by interfacing with external devices like safety interlocks, emergency stops, and remote control units. The reliable data transfer and control signals enabled by these robust connections are essential for achieving the precise, efficient, and high-quality welds characteristic of laser water pipe welding. This combination of precise laser application and robust connectivity ensures the long-term reliability and integrity of welded water pipe systems.

- 2. Temperature Monitoring and Control Systems in Restaurants:

In the competitive restaurant industry, maintaining high standards of food safety and quality is essential. Temperature monitoring and control systems for grills, smokers, and ovens have become indispensable tools for optimizing cooking processes while ensuring compliance with health regulations. These advanced systems utilize sophisticated sensors to provide real-time data on cooking temperatures, allowing chefs to maintain optimal conditions. Many systems feature user-friendly USB interfaces for easy programming and integration with existing kitchen technologies. A key benefit of these systems is their automated data logging capability, which simplifies compliance with health standards by continuously recording temperature data. They can also generate reports necessary for Hazard Analysis Critical Control Point (HACCP) documentation, helping restaurants adhere to rigorous food safety protocols.

- 3. Oil and Gas Equipment:

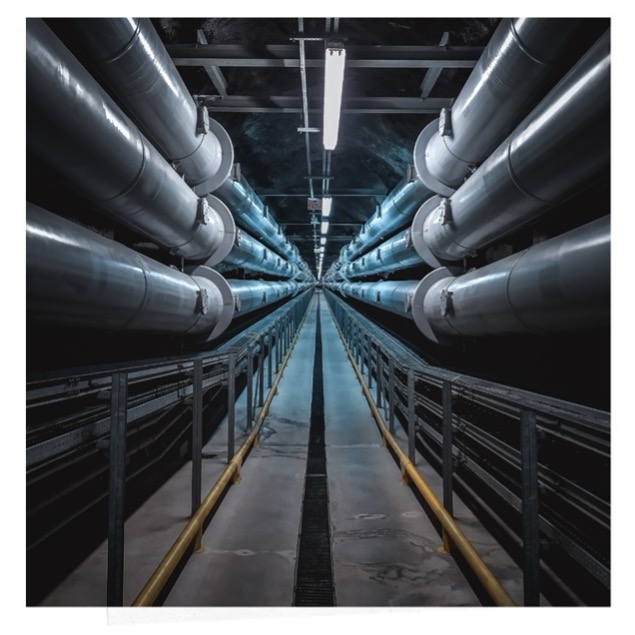

Oil and gas operations, from fuel management and tank gauging to facility and tanker automation, demand robust and reliable equipment capable of withstanding harsh environmental conditions. These systems, often deployed in remote or offshore locations, face constant exposure to moisture, saltwater, chemicals, and extreme temperatures. IP-rated sensor connectors are therefore essential for ensuring the integrity and functionality of critical instrumentation. Fuel management systems rely on accurate measurements from level sensors, flow meters, and temperature probes, all requiring secure, waterproof connections. Tank gauging systems, used to monitor liquid levels in storage tanks, utilize radar, ultrasonic, or pressure sensors, which must maintain reliable communication through waterproof connectors to prevent inaccurate readings and potential spills. Automation systems for fuel storage facilities and tankers depend on a network of sensors and actuators, necessitating robust, waterproof connections to ensure seamless control and data acquisition. In these applications, waterproof connectors prevent water ingress, corrosion, and electrical failures, ensuring continuous operation and minimizing downtime. These connectors are typically designed with oil-proof materials, such as stainless steel 303 or 304 housing and Viton gaskets, specialized sealing mechanisms, and high Ingress Protection (IP) ratings, such as IP67 or IP68, to withstand harsh conditions. The reliability of these waterproof connections is paramount for safety, efficiency, and environmental protection in the oil and gas industry. They safeguard against costly equipment failures, data loss, and potential environmental hazards, ensuring continuous and safe operation.